SBR10150CTFP

Product Overview

Category

The SBR10150CTFP belongs to the category of Schottky Barrier Rectifiers.

Use

It is commonly used in power supply applications, as well as in various electronic circuits where low forward voltage drop and high switching speed are required.

Characteristics

- Low forward voltage drop

- High switching speed

- High thermal stability

- Low leakage current

Package

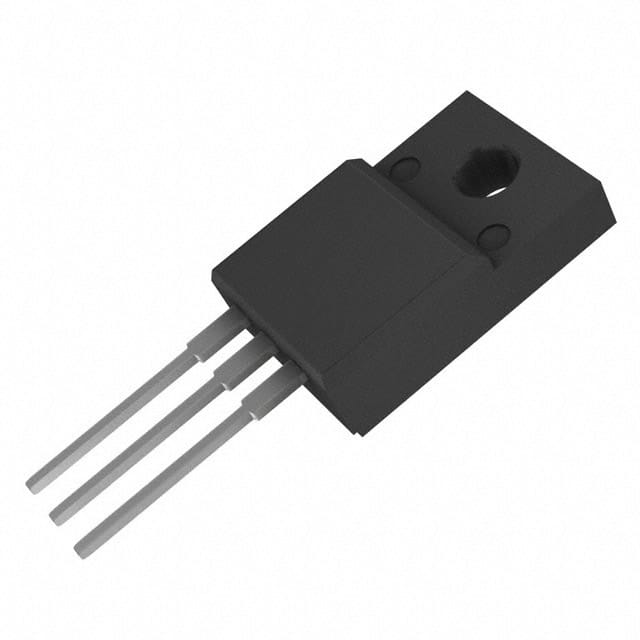

The SBR10150CTFP is typically available in a TO-220F package.

Essence

This rectifier is essential for converting alternating current (AC) to direct current (DC) with minimal energy loss.

Packaging/Quantity

The SBR10150CTFP is usually packaged in reels or tubes, with quantities varying based on manufacturer specifications.

Specifications

- Maximum Average Forward Current: 10A

- Maximum Reverse Voltage: 150V

- Forward Voltage Drop: 0.55V at 5A

- Reverse Leakage Current: 20μA at 150V

- Operating Temperature Range: -65°C to 175°C

Detailed Pin Configuration

The SBR10150CTFP typically has three pins: 1. Anode 2. Cathode 3. Gate (for some models)

Functional Features

- Fast switching capability

- Low power dissipation

- High efficiency

- Reliable performance over a wide temperature range

Advantages and Disadvantages

Advantages

- Low forward voltage drop reduces power loss

- High switching speed allows for efficient operation

- High thermal stability ensures reliability in various conditions

Disadvantages

- Higher cost compared to standard rectifiers

- Limited reverse voltage compared to some alternatives

Working Principles

The SBR10150CTFP operates based on the Schottky barrier principle, which involves the formation of a metal-semiconductor junction with a low forward voltage drop and fast switching characteristics.

Detailed Application Field Plans

The SBR10150CTFP is widely used in: - Switching power supplies - DC-DC converters - Motor control circuits - Solar panel bypass diodes - LED lighting applications

Detailed and Complete Alternative Models

Some alternative models to the SBR10150CTFP include: - SBR1045CTFP - SBR1060CTFP - SBR1080CTFP - SBR10100CTFP

In conclusion, the SBR10150CTFP is a crucial component in various electronic applications due to its low forward voltage drop, high switching speed, and thermal stability. Its functional features, advantages, and application field plans make it an essential part of modern power electronics.

[Word count: 410]

Senaraikan 10 soalan dan jawapan biasa yang berkaitan dengan aplikasi SBR10150CTFP dalam penyelesaian teknikal

What is SBR10150CTFP?

- SBR10150CTFP is a styrene-butadiene rubber (SBR) compound with high resilience and tensile strength, commonly used in technical solutions requiring durable elastomeric materials.

What are the key properties of SBR10150CTFP?

- SBR10150CTFP exhibits excellent abrasion resistance, good aging characteristics, and high tear strength, making it suitable for various technical applications.

In what technical solutions can SBR10150CTFP be used?

- SBR10150CTFP is commonly employed in tire manufacturing, conveyor belts, industrial hoses, and other applications requiring resilient and durable rubber compounds.

How does SBR10150CTFP compare to other rubber compounds?

- SBR10150CTFP offers a balance of performance and cost-effectiveness, making it a popular choice for technical solutions where durability and affordability are essential.

What are the temperature limits for SBR10150CTFP?

- SBR10150CTFP typically operates within a temperature range of -40°C to 100°C, making it suitable for a wide variety of technical environments.

Is SBR10150CTFP resistant to chemicals and oils?

- SBR10150CTFP has moderate resistance to chemicals and oils, but specific formulations may be available for applications requiring enhanced resistance.

Can SBR10150CTFP be customized for specific technical requirements?

- Yes, SBR10150CTFP can be formulated with additives or fillers to meet specific technical requirements such as improved weather resistance or electrical conductivity.

What are the curing methods for SBR10150CTFP?

- SBR10150CTFP can be cured using various methods including compression molding, injection molding, and extrusion, providing flexibility in manufacturing processes.

Does SBR10150CTFP comply with industry standards and regulations?

- SBR10150CTFP is designed to meet relevant industry standards and regulations for elastomeric materials, ensuring its suitability for technical applications.

Where can I obtain technical data and specifications for SBR10150CTFP?

- Technical data and specifications for SBR10150CTFP can be obtained from the manufacturer or supplier, providing detailed information on its physical and mechanical properties.