MC33186VW1

Product Overview

Category

MC33186VW1 belongs to the category of integrated circuits (ICs) specifically designed for motor control applications.

Use

This product is primarily used for controlling and driving motors in various electronic devices and systems.

Characteristics

- Integrated circuit designed for motor control

- High-performance and efficient motor control capabilities

- Compact package for easy integration into electronic systems

- Reliable and durable design for long-term use

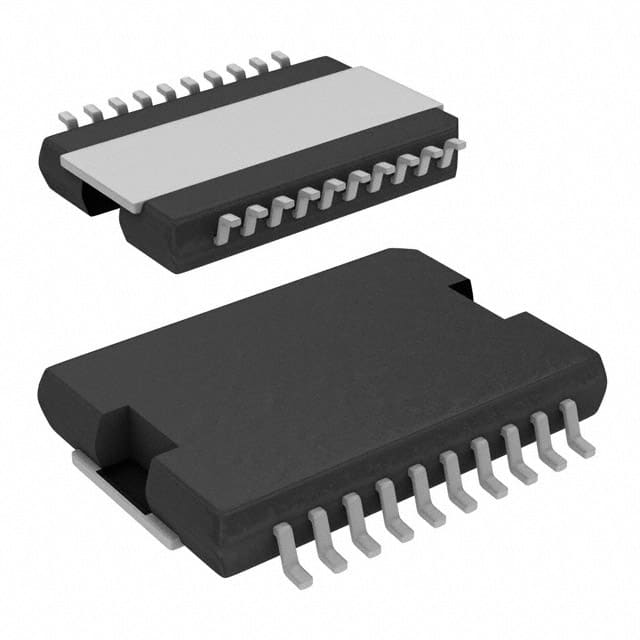

Package

MC33186VW1 is available in a small outline package (SOP) which ensures easy installation and compatibility with different electronic systems.

Essence

The essence of MC33186VW1 lies in its ability to provide precise and reliable motor control, enabling smooth operation and enhanced performance of electronic devices.

Packaging/Quantity

MC33186VW1 is typically packaged in reels or tubes, containing a specific quantity of ICs per package. The exact packaging and quantity may vary depending on the manufacturer and supplier.

Specifications

- Input voltage range: 4.5V to 28V

- Output current: up to 5A

- Operating temperature range: -40°C to +125°C

- Control interface: PWM (Pulse Width Modulation)

- Protection features: Overcurrent protection, thermal shutdown, and undervoltage lockout

Detailed Pin Configuration

MC33186VW1 has a total of 20 pins, each serving a specific function. The pin configuration is as follows:

- VCC - Power supply input

- GND - Ground reference

- IN1 - Motor input 1

- IN2 - Motor input 2

- IN3 - Motor input 3

- IN4 - Motor input 4

- OUT1 - Motor output 1

- OUT2 - Motor output 2

- OUT3 - Motor output 3

- OUT4 - Motor output 4

- VREF - Reference voltage input

- VCP - Charge pump capacitor connection

- CP1 - Charge pump capacitor connection

- CP2 - Charge pump capacitor connection

- CP3 - Charge pump capacitor connection

- CP4 - Charge pump capacitor connection

- FLT - Fault indication output

- PWM - Pulse Width Modulation input

- CS - Current sense output

- EN - Enable input

Functional Features

- Precise motor control with adjustable speed and direction

- Support for both forward and reverse motor rotation

- Built-in protection features to prevent damage from overcurrent, overheating, and undervoltage conditions

- Efficient power management for optimal energy usage

- Compatibility with various motor types, including DC motors and stepper motors

Advantages and Disadvantages

Advantages

- High-performance motor control capabilities

- Compact and easy-to-integrate package

- Reliable and durable design for long-term use

- Wide input voltage range for versatile applications

- Comprehensive protection features for enhanced safety

Disadvantages

- Limited output current capacity (up to 5A)

- Requires external components for complete motor control system implementation

- May not be suitable for high-power motor control applications

Working Principles

MC33186VW1 operates based on the principle of pulse width modulation (PWM) control. It receives control signals through the PWM input pin, which determines the motor speed and direction. The IC then processes these signals and drives the motor accordingly by controlling the output pins.

Detailed Application Field Plans

MC33186VW1 finds extensive application in various fields, including:

- Robotics: Used for precise motor control in robotic systems, enabling accurate movement and manipulation.

- Automotive: Employed in automotive systems for controlling motors in power windows, sunroofs, and other motorized components.

- Industrial Automation: Utilized in industrial automation equipment for motor control in conveyor belts, robotic arms, and other machinery.

- Consumer Electronics: Integrated into consumer electronic devices such as drones, cameras, and home appliances to control motorized functions.

Detailed and Complete Alternative Models

- L293D - Dual H-Bridge Motor Driver IC

- DRV8825 - Stepper Motor Driver IC

- TB6600 - Bipolar Stepper Motor Driver IC

- A4988 - Microstepping Motor Driver IC

- SN754410 - Quadruple Half-H Driver IC

These alternative models offer similar motor control capabilities and can be considered as alternatives to MC33186VW1 based on specific application requirements.

Word count: 579 words

Senaraikan 10 soalan dan jawapan biasa yang berkaitan dengan aplikasi MC33186VW1 dalam penyelesaian teknikal

Sure! Here are 10 common questions and answers related to the application of MC33186VW1 in technical solutions:

Q1: What is MC33186VW1? A1: MC33186VW1 is a motor driver IC (integrated circuit) designed for controlling brushed DC motors in various applications.

Q2: What voltage range does MC33186VW1 support? A2: MC33186VW1 supports a wide voltage range from 5V to 28V, making it suitable for a variety of motor control applications.

Q3: Can MC33186VW1 handle high current loads? A3: Yes, MC33186VW1 can handle peak currents up to 5A, making it suitable for driving motors with higher power requirements.

Q4: Does MC33186VW1 have built-in protection features? A4: Yes, MC33186VW1 includes various protection features such as overcurrent protection, thermal shutdown, and under-voltage lockout to ensure safe operation.

Q5: Is MC33186VW1 easy to interface with microcontrollers or other control systems? A5: Yes, MC33186VW1 has a simple interface that allows easy integration with microcontrollers or other control systems using standard logic-level inputs.

Q6: Can MC33186VW1 operate in both forward and reverse directions? A6: Yes, MC33186VW1 supports bidirectional control, allowing motors to be driven in both forward and reverse directions.

Q7: Does MC33186VW1 offer adjustable speed control? A7: Yes, MC33186VW1 provides adjustable speed control through pulse-width modulation (PWM) input, allowing precise motor speed regulation.

Q8: Can MC33186VW1 handle regenerative braking? A8: Yes, MC33186VW1 supports regenerative braking, allowing the motor to act as a generator and convert kinetic energy back into electrical energy.

Q9: Is MC33186VW1 suitable for battery-powered applications? A9: Yes, MC33186VW1 has low quiescent current consumption and can operate efficiently in battery-powered applications, helping to conserve power.

Q10: What are some typical applications of MC33186VW1? A10: MC33186VW1 is commonly used in robotics, automotive systems, industrial automation, consumer electronics, and other applications that require precise control of brushed DC motors.

Please note that these answers are general and may vary depending on specific implementation details and requirements.