FEP16JTA

Product Overview

Category

The FEP16JTA belongs to the category of semiconductor devices, specifically Schottky diodes.

Use

It is commonly used in electronic circuits for rectification and voltage regulation.

Characteristics

- Low forward voltage drop

- High switching speed

- Low reverse leakage current

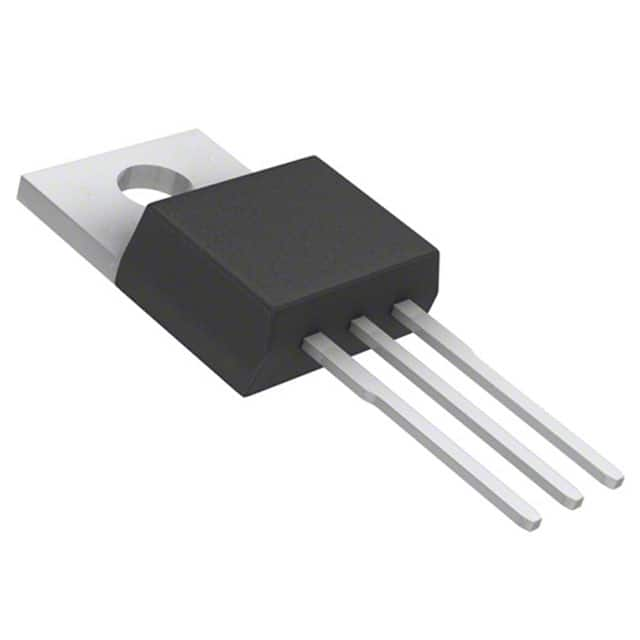

Package

The FEP16JTA is typically available in a surface mount package such as SMC or SMB.

Essence

The essence of the FEP16JTA lies in its ability to efficiently convert alternating current (AC) to direct current (DC) with minimal power loss.

Packaging/Quantity

The FEP16JTA is usually packaged in reels or tubes, with quantities varying based on manufacturer specifications.

Specifications

- Forward Voltage Drop: 0.55V

- Reverse Leakage Current: 10μA

- Maximum Continuous Forward Current: 1A

- Maximum Reverse Voltage: 60V

Detailed Pin Configuration

The FEP16JTA typically has two pins, with the anode connected to the positive terminal and the cathode connected to the negative terminal.

Functional Features

- Fast switching capability

- Low power dissipation

- High temperature operation

Advantages and Disadvantages

Advantages

- Efficient energy conversion

- Compact size

- Suitable for high-frequency applications

Disadvantages

- Limited maximum current handling capacity

- Vulnerable to overvoltage conditions

Working Principles

The FEP16JTA operates based on the principles of Schottky barrier rectification, where the metal-semiconductor junction allows for low forward voltage drop and fast switching characteristics.

Detailed Application Field Plans

The FEP16JTA is widely used in: - Power supplies - Voltage clamping circuits - Switching regulators - Solar panel bypass diodes

Detailed and Complete Alternative Models

Some alternative models to the FEP16JTA include: - 1N5817 - SS14 - SB160

In conclusion, the FEP16JTA is a versatile semiconductor device with efficient rectification capabilities, making it suitable for various electronic applications.

Word Count: 297

Senaraikan 10 soalan dan jawapan biasa yang berkaitan dengan aplikasi FEP16JTA dalam penyelesaian teknikal

What is FEP16JTA?

- FEP16JTA is a type of fluorinated ethylene propylene (FEP) material commonly used in technical solutions for its excellent electrical and thermal properties.

What are the key features of FEP16JTA?

- FEP16JTA offers high electrical insulation, chemical resistance, and low friction, making it suitable for various technical applications.

In what technical applications can FEP16JTA be used?

- FEP16JTA is commonly used in wire and cable insulation, semiconductor manufacturing, and as a coating for components in harsh environments.

What temperature range can FEP16JTA withstand?

- FEP16JTA has a wide temperature range, typically from -200°C to 200°C, making it suitable for both cryogenic and high-temperature applications.

Is FEP16JTA resistant to chemicals?

- Yes, FEP16JTA exhibits excellent resistance to a wide range of chemicals, including acids, bases, and solvents.

Can FEP16JTA be used for medical applications?

- Yes, FEP16JTA is often used in medical devices and equipment due to its biocompatibility and sterilization resistance.

Does FEP16JTA have good adhesion properties?

- FEP16JTA has low surface energy, which can make adhesion challenging, but proper surface preparation can improve adhesion.

Is FEP16JTA suitable for outdoor applications?

- Yes, FEP16JTA is UV-resistant and weather-resistant, making it suitable for outdoor use in various technical solutions.

Can FEP16JTA be molded into complex shapes?

- Yes, FEP16JTA can be molded using conventional thermoplastic processing methods, allowing for the creation of complex shapes and parts.

Are there any safety considerations when working with FEP16JTA?

- When processing FEP16JTA, proper ventilation and personal protective equipment should be used to minimize exposure to fumes. Additionally, care should be taken to avoid overheating the material, which can release toxic fumes.