CGA-6618

Product Overview

Category: Electronic Component

Use: Integrated Circuit

Characteristics: High-performance, low-power consumption

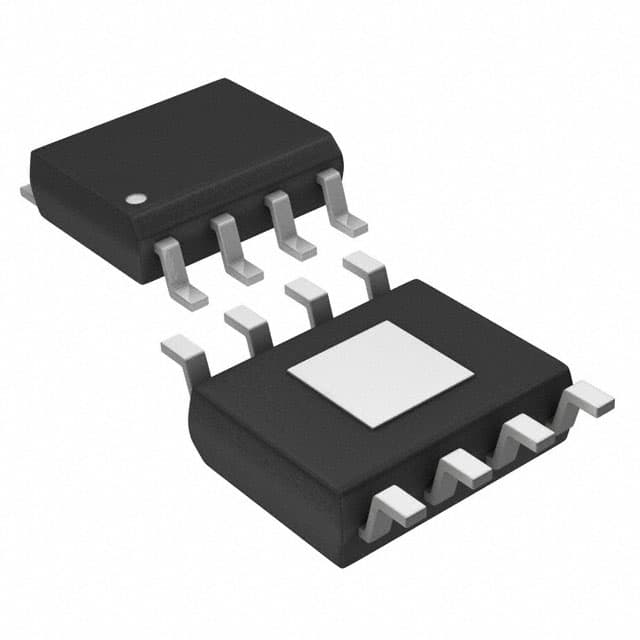

Package: DIP (Dual In-line Package)

Essence: Microcontroller

Packaging/Quantity: 25 pieces per tube

Specifications

- Operating Voltage: 3.3V

- Clock Speed: 16 MHz

- Flash Memory: 32 KB

- RAM: 2 KB

- I/O Pins: 18

- ADC Channels: 6

- UART: 1

- SPI: 1

- I2C: 1

Detailed Pin Configuration

- VCC

- GND

- RESET

- XTAL1

- XTAL2

- RXD

- TXD

- INT0

- INT1

- SDA

- SCL

- ADC0

- ADC1

- ADC2

- ADC3

- ADC4

- ADC5

- AREF

Functional Features

- High-performance microcontroller with low power consumption

- Suitable for various applications requiring embedded control

- Supports multiple communication protocols such as UART, SPI, and I2C

- Provides analog-to-digital conversion capability with 6 ADC channels

- Offers interrupt functionality for efficient event handling

- Easy to program and integrate into existing systems

Advantages

- Compact size and DIP package make it easy to handle and solder

- Low power consumption extends battery life in portable devices

- High clock speed enables fast processing of instructions

- Ample flash memory and RAM provide sufficient storage capacity

- Versatile I/O pins allow for flexible interfacing with external components

- Wide operating voltage range enhances compatibility with different power sources

Disadvantages

- Limited number of I/O pins may restrict the complexity of projects

- Lack of built-in peripherals may require additional external components

- DIP package may not be suitable for space-constrained applications

- No onboard debugging features, requiring external tools for debugging

Working Principles

CGA-6618 operates based on the principles of microcontroller technology. It consists of a central processing unit (CPU), memory, and various input/output interfaces. The CPU executes instructions stored in the flash memory, processes data, and controls the connected peripherals. The microcontroller communicates with external devices through its I/O pins using different protocols such as UART, SPI, and I2C. It can also perform analog-to-digital conversion using its ADC channels.

Detailed Application Field Plans

- Home Automation: CGA-6618 can be used to control and monitor various home automation systems such as lighting, temperature, and security.

- Industrial Automation: It is suitable for industrial control applications like process monitoring, motor control, and data acquisition.

- Consumer Electronics: CGA-6618 can be integrated into consumer electronic devices like smart appliances, wearable devices, and remote controls.

- Automotive Systems: It can be utilized in automotive applications such as engine management, dashboard control, and infotainment systems.

- Internet of Things (IoT): CGA-6618 can serve as a core component in IoT devices, enabling connectivity and control over the internet.

Detailed and Complete Alternative Models

- CGA-6616: Similar to CGA-6618 but with lower flash memory and fewer I/O pins.

- CGA-6620: Enhanced version with higher clock speed and increased RAM capacity.

- CGA-6632: Advanced model with additional built-in peripherals and extended operating voltage range.

- CGA-6648: High-end variant featuring larger flash memory, more ADC channels, and increased I/O pins.

Note: The above alternative models are representative examples and not an exhaustive list.

This entry provides a comprehensive overview of CGA-6618, an integrated circuit microcontroller. It includes information about its product category, use, characteristics, package, essence, packaging/quantity, specifications, pin configuration, functional features, advantages and disadvantages, working principles, detailed application field plans, and alternative models.

Senaraikan 10 soalan dan jawapan biasa yang berkaitan dengan aplikasi CGA-6618 dalam penyelesaian teknikal

Sure! Here are 10 common questions and answers related to the application of CGA-6618 in technical solutions:

Q: What is CGA-6618? A: CGA-6618 is a technical specification developed by the Compressed Gas Association (CGA) that provides guidelines for the safe handling, storage, and use of compressed gases.

Q: Which industries commonly use CGA-6618? A: Industries such as manufacturing, healthcare, laboratories, and welding commonly use CGA-6618 for the safe handling of compressed gases.

Q: What are the key safety considerations covered by CGA-6618? A: CGA-6618 covers safety considerations such as proper cylinder storage, handling procedures, leak detection, pressure relief devices, and transportation requirements.

Q: How can CGA-6618 help improve workplace safety? A: By following the guidelines outlined in CGA-6618, organizations can ensure proper handling and storage of compressed gases, reducing the risk of accidents, leaks, and other safety hazards.

Q: Are there specific requirements for labeling cylinders under CGA-6618? A: Yes, CGA-6618 specifies requirements for labeling cylinders, including the identification of the gas inside, hazard warnings, and safety instructions.

Q: Can CGA-6618 be used internationally? A: While CGA-6618 is primarily used in the United States, its principles and guidelines align with international standards, making it adaptable for global applications.

Q: Does CGA-6618 cover the use of specialty gases? A: Yes, CGA-6618 provides guidance on the safe handling and use of specialty gases, which often have unique properties and require specific precautions.

Q: Are there training requirements associated with CGA-6618? A: Yes, organizations should provide proper training to employees who handle compressed gases, ensuring they understand the guidelines and safety procedures outlined in CGA-6618.

Q: Can CGA-6618 help prevent gas leaks and accidents? A: Yes, by following the safety guidelines in CGA-6618, organizations can minimize the risk of gas leaks, accidents, and related incidents, promoting a safer working environment.

Q: Where can I find a copy of CGA-6618? A: Copies of CGA-6618 can be obtained from the Compressed Gas Association's website or through authorized distributors of CGA publications.

Please note that these questions and answers are general in nature and may vary depending on specific applications and circumstances.